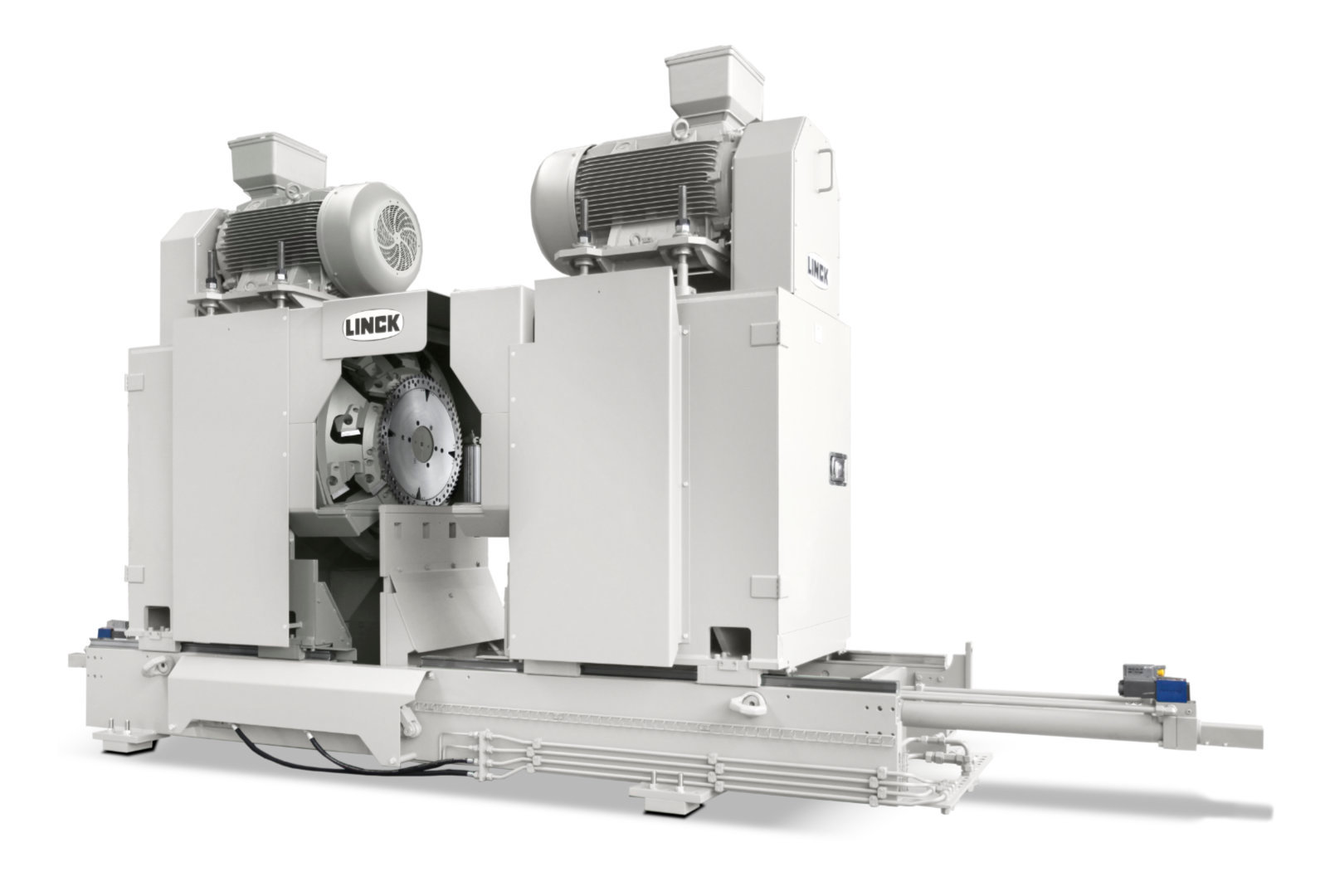

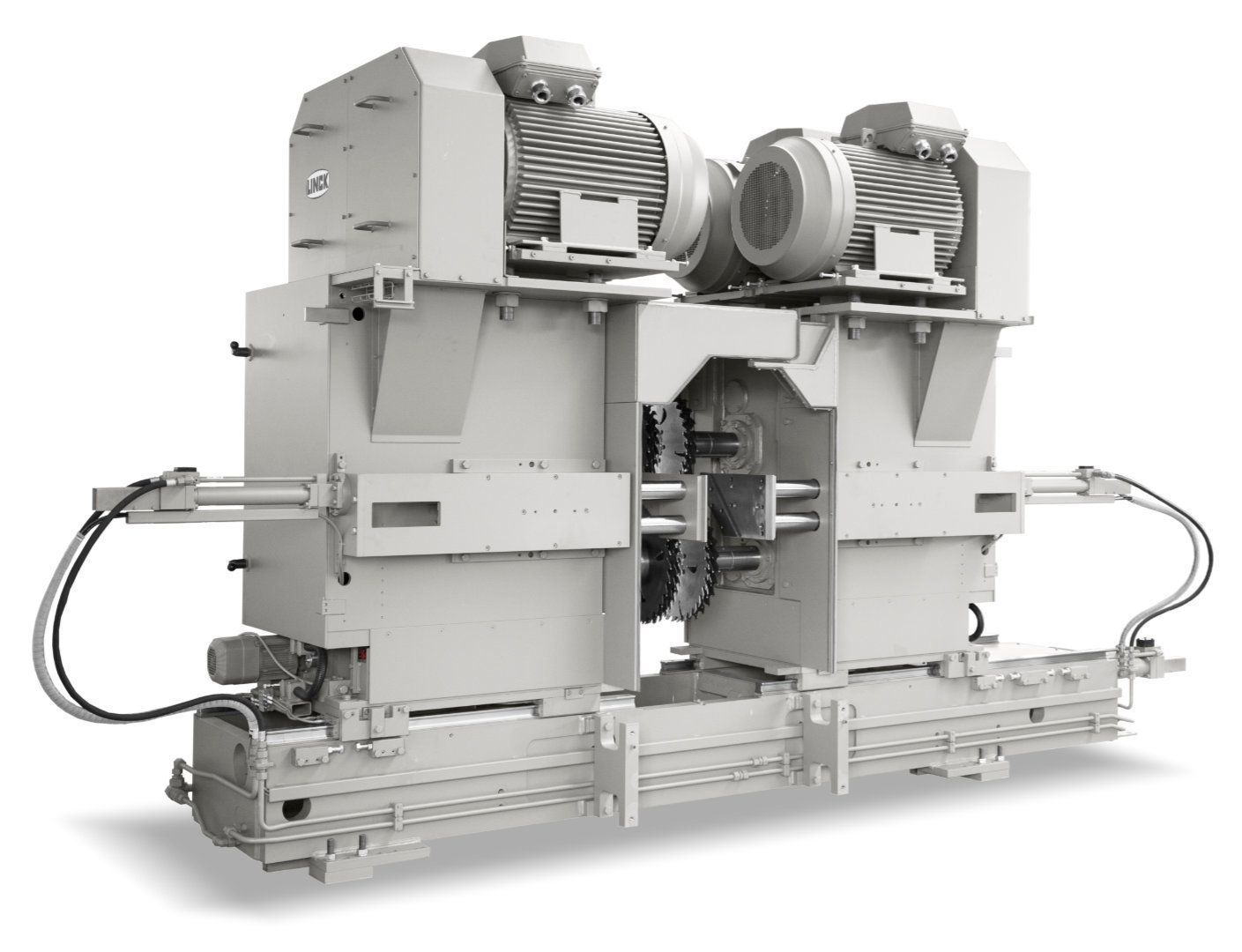

RED L

Your compact reducer line with high capacity

The reducer line RED L will convince you with its high capacity and economical space requirement. On the base of the 3D-data evaluation, the chipper canter-circular saw line with reducer technology processes every log with the optimum cutting pattern. For this purpose, the automatic log rotation and, if necessary, the off-centre or diagonal resawing technology are used. To ensure that the reducer line RED L exactly meets your requirements, we design the saw line down to the last detail.

Key data

- Processing up to 250.000 m³ of round logs per year and shift

- Feed speed from 24 to 100 m/min and more - depending on the configuration

- Operating mode: processing of unsorted logs

- Log diameter, large end, max. 50 cm

- Log diameter, small end, 10 cm

- Log length 2,50-4,20 m