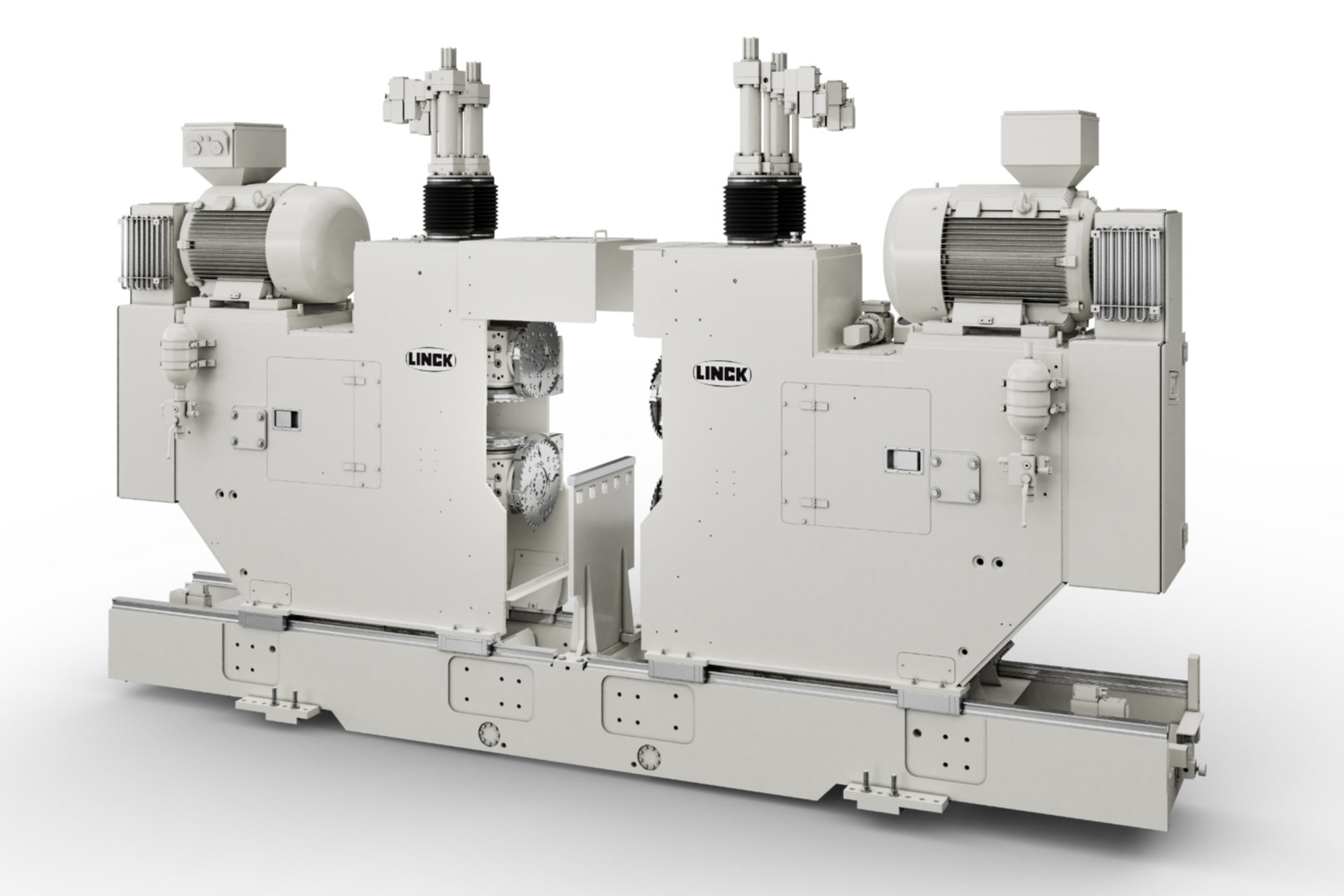

Profiler Unit VPM

Auf einen Blick

Das Profilieraggregat VPM 450 profiliert auf den zwei seitlichen Flächen eines Models oder Kantholzes je ein Seitenbrett. Hierzu sind pro Seite zwei Werkzeugeinheiten im Einsatz, die das Brett am Model oder Kantholz erzeugen und hierfür das waldkantige Material entfernen. Jede der insgesamt vier Werkzeugeinheiten wird mit einem Drehstrommotor angetrieben. Für maximale Ausbeute können die Werkzeugeinheiten optional per Bahnsteuerung geschwenkt oder genickt werden. Dies ermöglicht den bogenfolgenden Einschnitt oder diagonal am Holz profilierte Seitenbretter. Die Werkzeugeinheit mit zwei rechtwinklig zueinander angeordneten Sägeblättern sorgt für ausrissfreie Oberflächen.

Die Maschinenhälften der VPM sind auf Linearführungen gelagert. Die Führungslänge ist so gewählt, dass in Werkzeugwechselposition ein großzügig bemessener Raum für den Werkzeugwechsel vorhanden ist. Die Breitenverstellung der Maschine kann servohydraulisch oder mit elektrisch angetriebener Kugelrollspindel erfolgen. Um kurze Werkzeugverstellzeiten zu erreichen, wurde die zu bewegende Masse gering gehalten. Bei schwenkender oder nickender Funktion werden jeweils nur die Werkzeugeinheiten bewegt, nicht die ganze Maschine. Durch die kurze Verstellzeit und die äußerst kompakte Werkzeugeinheit werden auch beim unsortierten Einschnitt und beim Einschnitt mit Seitenwarenoptimierung minimale Holzlücken erreicht. Die Motorisierung mit maximal 4 x 132 kW lässt auch große Zerspanungsquerschnitte bei hohem Vorschub zu.

Werkzeugeinheit

Pro Ecke sorgt eine patentierte Werkzeugeinheit bestehend aus Fräskopf und einem in derselben Ebene um 90° versetzt angeordnetem Sägeblatt für ausrissfreie Schnittflächen. Der synchrone Lauf der Werkzeuge wird durch ein speziell entwickeltes Hochleistungsgetriebe sichergestellt. Dies ermöglicht, dass die Werkzeuge kämmend angeordnet werden können.

Bahngesteuertes Diagonalfräsen

Die Werkzeugeinheiten jeder Maschinenseite können im Maschinengehäuse um eine gemeinsame Achse in oder gegen Förderrichtung nicken und gleichzeitig in der Höhe verfahren. Die vertikale Bewegung erfolgt bahngesteuert durch hydraulische Servozylinder. Diese Funktion ermöglicht es, ein Seitenbrett unter Berücksichtigung der Stammform diagonal zur Holzauflage zu profilieren. Die damit erzielbare Ausbeute entspricht der einer Besäumanlage.

Aktiv bogenfolgenden Nachschnitt

Die VPM /S ist mit innerhalb der Maschine liegenden, senkrechten Schwenkachsen ausgestattet. Diese ermöglichen, dass die Fräser beider Seiten unabhängig voneinander geschwenkt werden können. Somit ist die Maschine in dieser Ausführung für den aktiv bogenfolgenden Nachschnitt geeignet.

NONstop concept

Die Produktion fortsetzen und gleichzeitig Wartungsarbeiten durchführen, ist nicht nur ein Wunsch von vielen Sägewerksbetreibern, sondern auch seit kurzem mit der Tunnelausführung Realität geworden. Ein Tunnel wird durch die weite Öffnung der VPM gebildet und durch Bleche gesichert. Somit kann der Werkzeugwechsel an einem Profilieraggregat realisiert werden, während die restliche Anlage weiterhin Hölzer bearbeitet. Jedes Profilieraggregat ist auf diese Weise frei zugänglich und alle Werkzeuge der Einheit können nacheinander gewechselt werden.