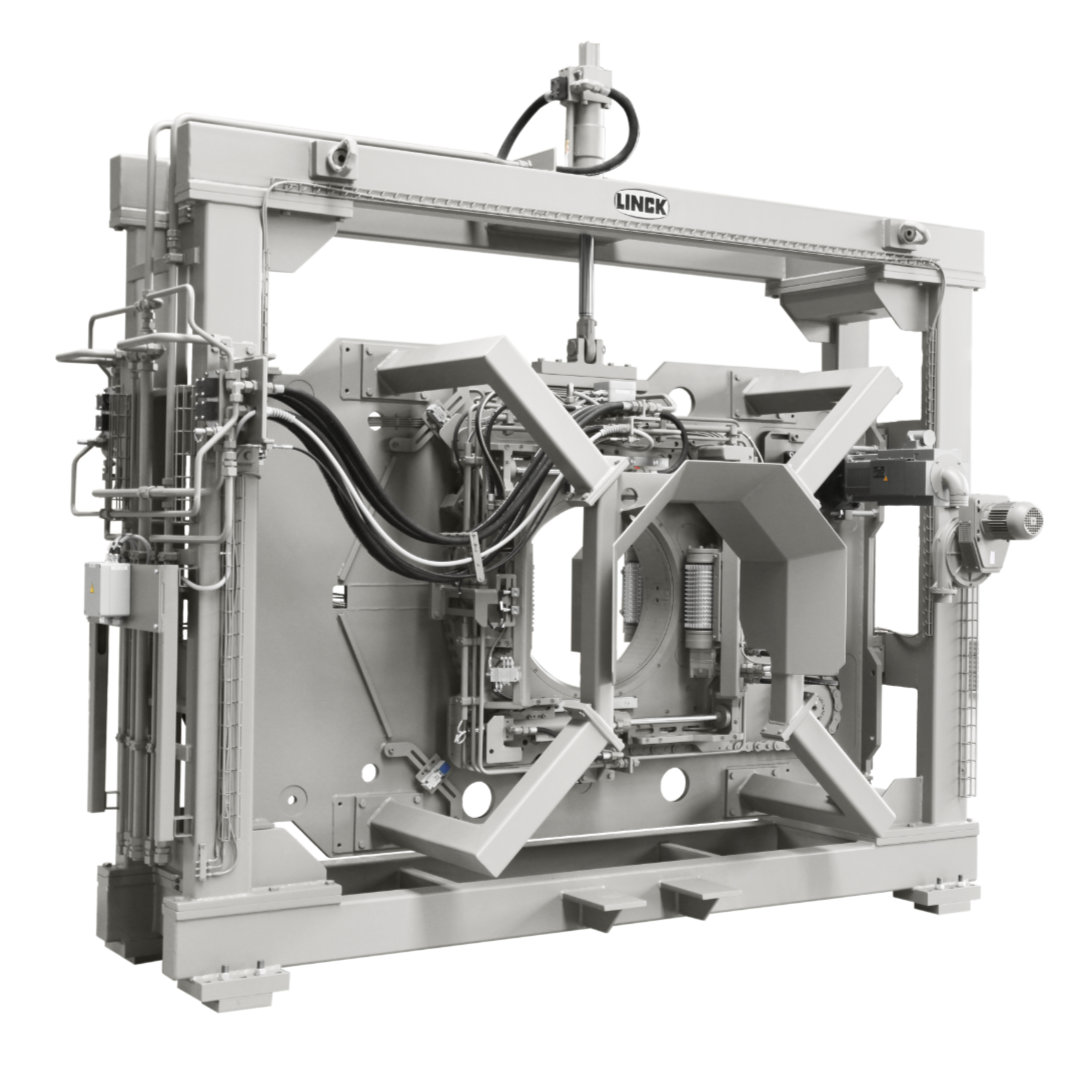

Cant turner DV

Auf einen Blick

Die Drehvorrichtung dreht Model und Kantlinge im Längsdurchlauf um 90 Grad. Die Rotoren sind in Großwälzlagern gelagert und in einem in der Höhe verstellbaren Rahmen im Maschinengestell montiert.

Durch den Einsatz eines hydraulischen Servozylinders für die Höhenverstellung kann der Rotor bei Einsatz einer entsprechenden Messung auf die Holzmitte vorpositioniert werden. Während des Drehvorgangs wird der Rotor gemeinsam mit dem Holz angehoben, um eine Beschädigung der Kanten zu vermeiden. Die Drehbewegung der Rotoren wird über in den Motoren integrierten Drehgebern geregelt und mit externen Signalgebern überwacht. Auf den Rotoren ist jeweils ein hydraulisch angetriebenes Walzenpaar angebracht, das während des Längsdurchlaufes servohydraulisch an das Holz angepresst wird und für Führung und Vorschub sorgt. Die Walzen werden entsprechend dem zu drehenden Holz vorpositioniert, wodurch eine hohe Stückfolge erreicht wird.

Hohe Leistung durch Einsatz zweier abwechselnd arbeitender Rotoren

Die Drehvorrichtungen dieser Modellreihe können wahlweise mit einem oder zwei separat angetriebenen Rotoren ausgeführt werden. Beim Einsatz von zwei Rotoren werden diese abwechselnd eingesetzt, womit sich die erreichbare Stückzahl deutlich erhöht. Je nach Erfordernis ist es möglich, bei gleichbleibender Leistung entweder alle Hölzer in die gleiche Richtung oder wechselseitig zu drehen.