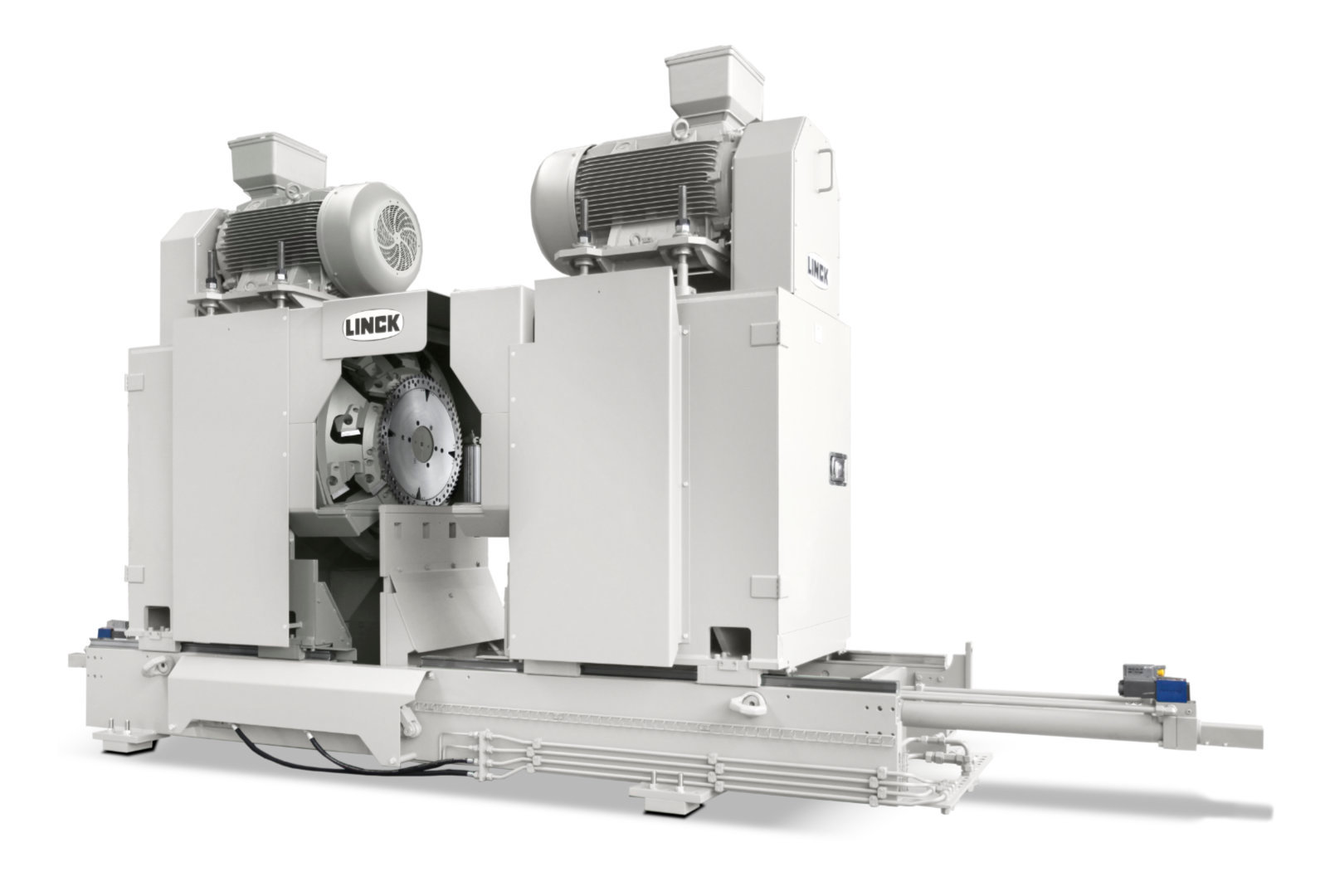

Chipper Canter VM45 / VM50

Auf einen Blick

Die Profilspaner kommen im Vor- und Nachschnitt zum Einsatz. Sie erzeugen zwei planparallele Flächen an Rundholz oder Model. Beim Einsatz als Vorschnittmaschine wird aus einem Rundholz ein Model erzeugt. Im Nachschnitt ergibt sich aus einem Model ein Kantholz. Die beim Zerspanungsprozess anfallenden Hackschnitzel können durch Umrüsten der Messerköpfe den Erfordernissen angepasst werden. So sind einerseits hochwertige Hackschnitzel für die Zellulose- und Papierindustrie ebenso möglich wie Feinhackschnitzel zur Pelletsproduktion.

Werkzeugwechsel

Bei der Auslegung der Profilspaner wurde größter Wert auf Bedienerfreundlichkeit gelegt. Die Linearführungen zum Verschieben der Maschinenoberteile sind asymmetrisch ausgelegt. Auf der Werkzeugwechselseite sind sie verlängert, um die Maschine weit auseinanderfahren zu können. Dadurch ergibt sich ein großzügig bemessener Raum für den Werkzeugwechsel. Für einen sicheren Stand lässt sich die Holzauflage hydraulisch um 90° schwenken und ergibt so eine Plattform.

Messerkopf

Die Messerköpfe haben ein hohes Gewicht, wodurch ein ruhiger Lauf sichergestellt wird. Durch die großen Öffnungen in den Messerköpfen werden die Hackschnitzel schonend abgeleitet. Je nach Schnitttiefe sind die Köpfe zwei- oder dreistufig ausgeführt. Die Anzahl der Hackmesser pro Stufe ist abhängig von Vorschub, Drehzahl und der gewünschten Hackschnitzellänge. Je nach Einsatzbedingungen können wahlweise Sägeringe oder Schlichtmesser eingesetzt werden. Die in den Köpfen eingebauten, separat gelagerten Teller dienen der Führung des Holzes und wirken sich somit positiv auf die Maßhaltigkeit der Schnittware aus.